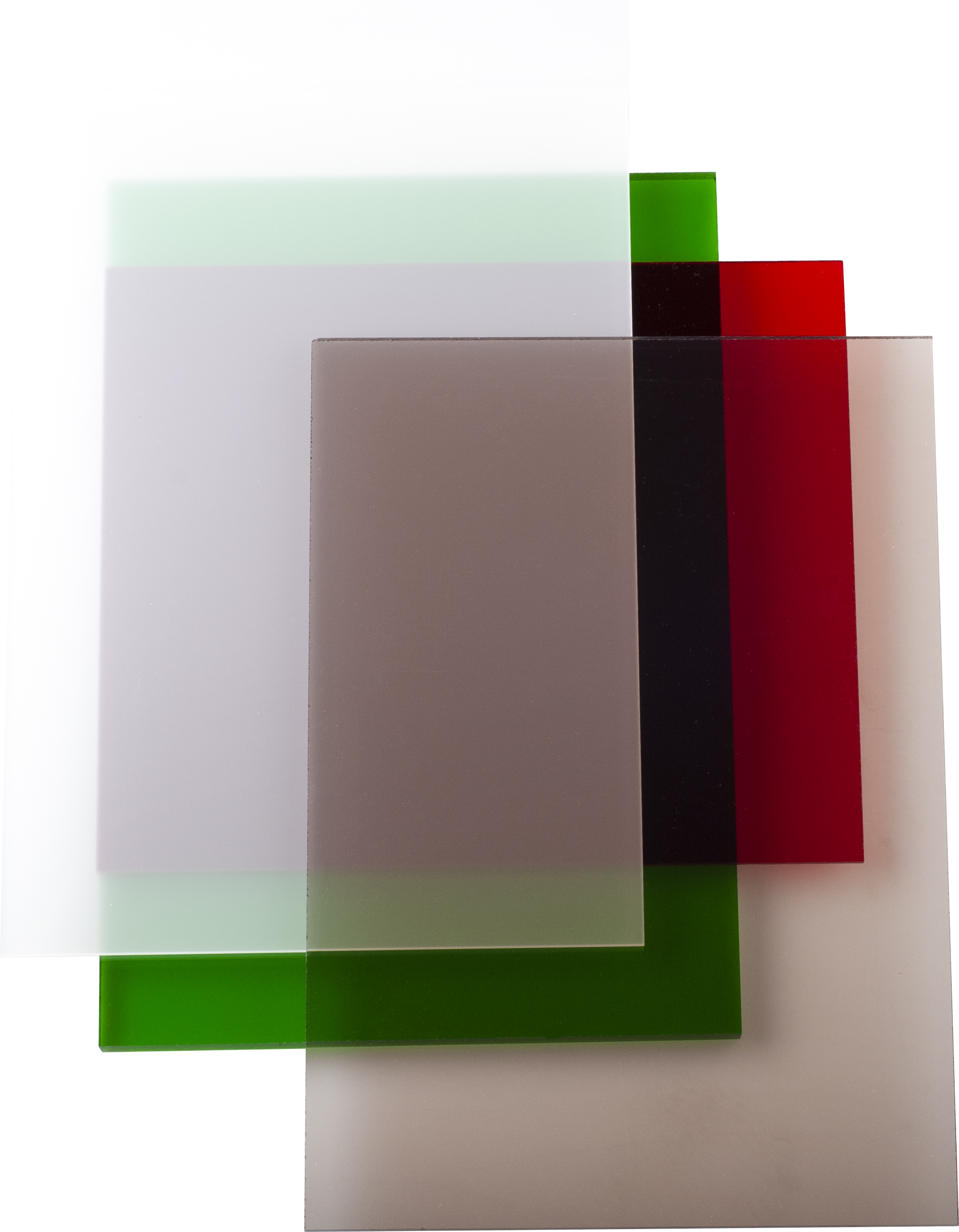

LUPET® stands for extruded transparent and translucent A-PET & PET-G polyester sheets

Both products ensure excellent printing results with UV-resistant inks, have a high level of impact resistance, are easy and fast to process and the UV protection version offers good resistance to weathering.

In addition, “LUPET ” is classed as “difficult to-ignite” and suitable for food applications

The LUPET ” product range is the ideal choice for forming. LUPET® A (A-PET) is especiallysuitable for cold-bending applications, LUPET® G (PET-G) for vacuum and thermoforming.

LUPET® A is available in thicknesses of 0.35 to 5 mm, LUPET® G in thicknesses from 0.35 to 12 mm and up to a width of 2050 mm.

A CLEAR CHOICE

| CHARACTERISTICS

◆ High transparency ◆ Very high impact strength ◆ Good outdoor durability in the variant with UV protection ◆ Fire behavior according to EN 13501-1: B-s1, d0 “difficult-to-ignite” ◆ Very good chemical resistance ◆ Easy and fast to process ◆ Good printability thanks to optimal adhesion of UV curing inks |

|

| APPLICATION

◆ Displays (POS/POP) ◆ Signage l Lettering ◆ Shop design I Shop window decoration ◆ Interior design I Furniture ◆ Partitions I Cladding ◆ Lighting l Light boxes ◆ Glazing ◆ Food contact approved |

|

| PROCESSING

◆ Digital printing l Screen printing ◆ Laminating ◆ Painting l Spray paintingl Lacquering ◆ Contour milling ◆ Laser cutting ◆ Water jet cutting ◆ Sawing I Punching ◆ Gluing ◆ Drilling l Screwing ◆ Thread cutting ◆ Folding (V-groove) l Cold bending ◆ Hot bending ◆ Thermoforming ◆ Engraving |

|

| PRODUCTS | LUPET®A | LUPET®G | ||

| GENERAL | ||||

| Density | ISO 1183-1 | Kg/m³ | 1340 | 1270/1290 |

| Moisture absorption (23°C saturation in water) | ISO 62-1 | % | 0. | 0.6 |

| Biocompatibility (skin contact) | ISO 10993-5 | Classification | not cytotoxic | not cytotoxic |

| MECHANICAL | ||||

| Tensile modulus | IS0 527-2 | MPa | 2400 | 2000 |

| Tensile strength | IS0 527-2 | MPa | 55 | 50 |

| Elongation at break | IS0 527-2 | % | >25 | >35 |

| Flexural modulus | ISO 178 | MPa | 2400 | 2000 |

| Flexural strength | ISO 178 | MPa | 80 | 75 |

| Charpyimpact strength, unnotched | ISO 179-1/1eU | k]/m² | no break | no break |

| Charpyimpact strength, notched | ISO 179-1/1eU | k]/m² | 4 | 7 |

| Surface hardness | ISO 868 | Shore D | 50 | 40 |

| OPTICAL | ||||

| Light transmission (3 mm) | ISO 13468-1 | % | 88 | 88 |

| Refractive index | ISO 489 | – | 1.58 | 1.57 |

| Haze | ISO 14782 | % | >1 | >1 |

| Solar heat gain coefficient, g value (3 mm) | DIN EN 410 | % | 82 | 82 |

| THERMAL | ||||

| Temperature of deflection under load | IS0 75-2 | ℃ | 72/68 | 72/68 |

| Vicat softening temperature (method B50) | ISO 306 | ℃ | 70 | 70 |

| Coefficient of linear thermal expansion | ISO 11359-2 | mm/(m*K) | 0.05 | 0.05 |

| Service temperature continuous use | – | ℃ | 65 | 65 |

| Max. temperature short term use | – | ℃ | 70 | 70 |

| Degradation temperature | – | ℃ | >280 | >280 |

| Forming temperature | – | ℃ | 110-150 | 110-150 |

| Specific heat capacity | ISO 11357-4 | J/gK | 1.1 | 1.1 |

| Thermal conductivity | ISO 22007-1 | W/mK | 0.20 | 0.20 |

| EN 13501-1 | Class | B-s1. d0(clear 0.5-10mm color 1-5 mm) | B-s1. d0(clear 0.5-10mm color 1-5 mm) | |

| ELEKTRICAL | ||||

| Electric strength | IEC 60243-1 | kV/mm | 17 | 16 |

| Volume resistivity | IEC 62631-3-1 | Ωm | 10^15 | 10^15 |

| Surface resistivity | IEC 62631-3-2 | Ω | 10^16 | 10^16 |

| Dielectric constant (100 Hz) | IEC 60250 | – | 3.4 | 2.6 |

| Dissipation factor (50 Hz) | IEC 60250 | – | 0.02 | 0.01 |

THE BEST FOR FLAT AND COLD BENDING APPLICATIONS.

LUPET®A are premium quality amorphous polyethylene terephthalate (A-PET) sheets. They are ideally suited to flat and cold bending applications. LUPET® A shows good printability with UV curing inks and is flame retardant rated ‘difficult-to-ignite’ (Fire behavior according to EN 13501-1: B-s1, d0) as well as suitable for food applications. Moreover, it is extremely impact resistant also at temperatures down to -20°C and shows good outdoor durability in the variant with UV protection

LUPET®A sheets offer a unique combination of excellent properties and are well suited for e.g. flexible poster covers printed, translucent signs, small to medium sized displays, Slatwall magazine racks as well as for cold food storage elements

| CHARACTERISTICS

◆ 100% recyclable within its own waste category 1 (PET)Tough and hard with high impact strength also at temperaturesdown to -20°C ◆ Impeccable optical properties with a light transmissionof nearly 90% for non-tinted types ◆ Good outdoor durability in the variant with UV protectionFlame retardant rated B-s1, d0 according to EN 13501-1(difficult-to-ignite) ◆ Very high chemical resistance against cleaning agents,APPLICATION ◆ Displays (POS/POP) ◆ Signage l Lettering ◆ Shop design l Shop window decoration ◆ Interior design | Furniture ◆ Partitions l Cladding ◆ Lighting l Light boxes ◆ Glazing ◆ Suitable for food applications ◆ mineral oils, solvents ◆ Easy and fast to process ◆ Good printability thanks to optimal adhesion of UV curing inks |

|

| PROCESSING

◆ Digital printing l Screen printing ◆ Laminating ◆ Painting l Spray painting l Lacquering ◆ Contour milling ◆ Laser cutting ◆ Water jet cutting ◆ Sawing l Punching ◆ Gluing ◆ Drilling l Screwing ◆ Thread cutting ◆ Folding (V-groove) l Cold bending ◆ Engraving |

|

THE PERFECT MATERIAL FOR VACUUM FORMING AND THERMOFORMING.

·LUPET®G-SK (100% Virgin SK-2012 PETG RESIN)

·LUPET®G-CN (100% Virgin China PETG RESIN)

LUPET®G is the proven brand on the market for premium quality modified polyethylene terephthalate (PET-G). LUPET®G is the best choice for thermoforming and hot line bending applications. LUPET®G sheets are flame retardant rated “difficult-to-ignite” (fire behavior according to EN 13501-1: B-s1, d0), approved for use in the food industry and show very high impact-resistance. They are also excellent to print with UV curing inks and fast, convenient to convert.

LUPET®G sheets feature enhanced thermoforming capabilities as they do not crystalize. Vacuum forming requires no pre-drying and is therefore significantly quicker and more cost-effective.

LUPET®G sheets are suitable e.g. for all kinds of glazing (bus shelters, posters, machines), for medical appliance packaging displays and signs for interior and exterior use as well as for three-dimensional POS/POP displays.

| CHARACTERISTICS

◆ Excellent for vacuum forming and thermoforming without pre-drying (time and energy saving) ◆ Easy to fabricate ◆ Good chemical resistance ◆ Good outdoor durability in the variant with UV protection ◆ Very high impact strength ◆ Flame retardant rated B-s1, d0 according to EN 13501-1 (difficult-to-ignite) |

|

| APPLICATION

◆ Displays (POS/POP) ◆ Signage l Lettering ◆ Shop design I Shop window decoration ◆ Interior design | Furniture ◆ Partitions l Cladding ◆ Lighting l Light boxes ◆ Glazing ◆ Food contact approved ◆ Good printability thanks to optimal adhesion of UV curing inks |

WE USE TWO DIFFERENT PETG RESIN TO PRODUCE LUPET®G

LUPET®G-SK: means PETG SHEET which is made of 100% virgin PETG resin from South Korea

LUPET®G-CN: means PETG SHEET which is made of 100% virgin PETG resin from China

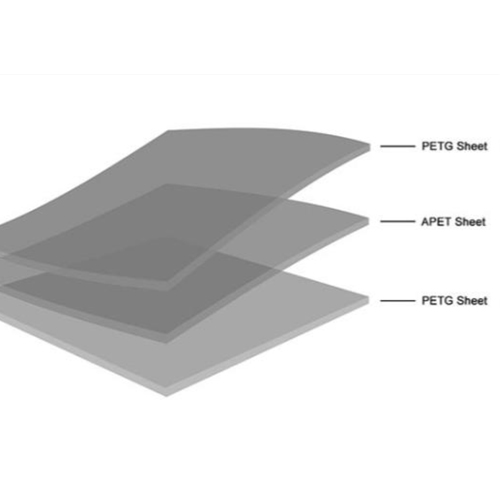

LUPET®GAG is laminated sheet made of A-PET (Amorphous Polyester) inner layer and PETG

(Amorphous Co-polyester) surface layer on both sides. It is suited for POP displays, etc.

Features

Adhesion

Comparing with regular LUPET®A sheet, LUPET®GAG has stronger adhesion strength due to the PETG surface layers.

Processability

Easy punching and bending by leading line. Less burring compared with LUPET®A materials.

Printing

Printing property is same as LUPET®G, better than LUPET®A.

Thermal forming

Vacuum forming and bending with heat process can be applied.

Applications

Interior Decoration for Stores

Signboard/Display

POP advertisement, display

LUPET® SURFACE GUARD

◆ LUPET®A SURFACE GUARD (A-PET)

◆ LUPET®GAG SURFACE GUARD(PET-GAG)

◆ LUPET®G SURFACE GUARD(PET-G)

Extruded Sheet (APET , PET-GAG, PETG) With Hard Surfaces

LUPET® Surface Guard extruded PET-GAG panel is a specialty developed PET grade, which is highly abrasion/mar resistant (pencil hardness 2H), exceptional chemical resistance, excellent clarity & optical properties, exceptional mechanical properties & rigidity, simple to fabricate, whilst meeting with the difficult challenges of public glazing applications.

CHARACTERISTICS

⚫ The surface is hard, durable and abrasion-resistant

⚫ Completely clear APET / PET-GAG / PETG

⚫ Perfect material for surface protections, glazing, guard screens, displays and more

⚫ Easily maintained with soap and warm water – no harsh chemicals needed

⚫ Supplied with protective film on both sides

⚫ One or two sides coated. (S1 & S2)

LUPET® Surface Guard displays fantastic resistance to abrasions and scratches when compared with standard clear APET or PETG. This makes it a very popular choice of material for machine guards, screens, secondary glazing, plastic greenhouse panels and many more, where its abrasion-resistant surface retains the clarity and glass-look aesthetic of the material.

Colour Availability: Clear as standard, other colours on request.

Surface Finish: Gloss

Std. Dimensions/panel sizes:

▪ 1830mm x 1220mm

▪ 2400mm x 1220mm

▪ Other sizes available on request.

Thicknesses: 0.2-10mm

Masking: Pressure Sensitive PE film